WHAT SHOULD MY LABOR RATE BE?

This is a great question that I am often asked. What makes this extremely important is that this number has a great impact on 2 of the 8 financial items that a service manager needs to control (effective rate, gross profit %). In addition, it could determine if you are adequately compensating your technicians. So, having the “correct” labor rate or effective labor rate can have a huge impact on your overall profitability.

The answer is simple: NADA Benchmark is 73+% for Customer Pay, Warranty and Internal labor categories. While the answer is “simple”, the means of accomplishing this and being fair in the marketplace might be a little more complicated. Here are the steps to determining this:

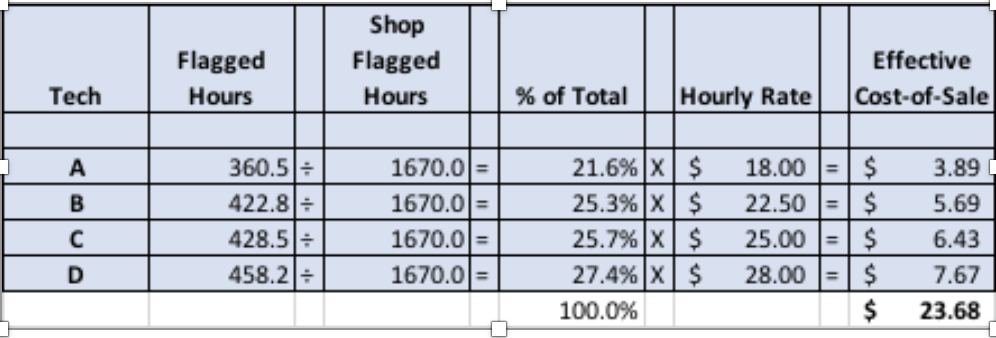

1. Determine your cost-of-sale: for a period (usually 10 weeks), calculate each technician’s flagged hours divided into total shop hours produced in the period, as a percentage. Multiply each technician’s hourly rate times the previous calculated percentage. Add the amounts up. Example:

2. Divide your Effective-Cost-Of-Sale into Desired Cost % (100-73=27%)... $23.68 /.27= $87.70 – This is your desired Effective Rate

3. Now to determine your Customer Pay Door Rate, you need to know what percentage of your CP labor is “maintenance” (oil changes, etc.) …and, what your “maintenance effective rate” is. There’s a pretty good chance that you can run a report in your DMS that will separate repair from maintenance by op code. If not, grab a spreadsheet (email me for a free copy) and a stack of 100 repair orders and figure it out. Example:

A. Stack of repair orders had 75.0 maintenance hours with an effective rate of $66.80

B. Stack of repair orders had 72.5 repair hours

C. 75.0 and 72.5 = 147.5 total hours (75.0 / 147.5 = 50.8% maintenance)

So, you need a Customer Pay “Door Rate” of $109.29. Many hi-line brands are able to exceed NADA benchmark and accomplish 80+% due to the ability to charge higher maintenance effective rates.

Once you have the correct customer pay door rate, it should be easy to implement the pricing policy for internal and, assuming that you are in a state that requires warranty retail pricing, to accomplish a nice labor rate for warranty repairs.

This information may be exactly what you need, or using this calculation…

• Your door rate would be too high, when compared to your market?

• Your door rate would be too low, when compared to your market?

• Your door rate is already higher but you’re not getting this gross percentage?

If either of these are the case, read on...

Let’s examine the three main challenges that you might have when calculating a door rate:

1. Based on your calculation, your door rate would be too high when compared to your market? If this is the issue, you will want to look at three main things…

A. Do you have an extremely high percentage of maintenance work? If the answer is yes (60-80%), you will need to look at the following:

- Are your maintenance labor prices too low? Shop your market for comparison. You shouldn’t want to be the low-cost provider.

- Is your team utilizing the multi-point inspection process and are you measuring results? Most MPI “upsells” should be, predominately, repair

items with the higher effective rate.

B. Is your technician “skill proficiency” too high? The calculation for this is, as follows:

- Rate each technician’s skill in the eight or nine repair areas:

1) Brakes

2) Electrical

3) Front End, Steering & Suspension

4) Engine Performance

5) Heating & A/C

6) Manual Transmission & Rear End

7) Automatic Transmission

8) Engine Repair

9) Diesel Engine Repair (if applicable)

Rate each technician, in each area as a "0", "1" or "2" - "0"=Unskilled, "1"= Somewhat Skilled, "2"=Highly Skilled

Add up your numbers and divide into the number of total techs X 16 (or 18 if diesel applies). Calculate as a %.

Match the calculated % to your actual “work mix”. Be sure to calculate warranty and internal into the work mix.

If you are over-skilled for the work-mix, you may need to hire lesser-skilled technicians to reduce your cost-of-sale.

C. Are you having to overpay your technicians? While the “skill proficiency” calculation ought to assist you in this, this could simply come down to

overpaying technicians as compared to the market.

- If this is true, and the “skill proficiency” is balanced, the cause would typically could be blamed on, either poor productivity or dealership

"environmental” issues

A) Poor Productivity - The average skilled technician should be well over 100% productive. If not…

- Do we have advisor selling issues?

- Do we have dispatch issues?

- Are we training technicians?

- Do we have parts issues?

- What is expected of our technicians? Do we have production objectives?

B) Environmental Issues – What is it like to work for your dealership versus your competition?

- Is your facility run down? If so, what can you do to improve?

- Do you have outdated, broken equipment?

- Do you have a lot of staff turnover? How do we treat our people? Too strict? Too lenient?

- Is parts procurement a real issue?

These are all items that could cause an environment that would force overpaying technicians just to keep them or having to pay more to hire

lesser-skilled technicians.

2. Based on your calculation, your door rate would be too low when compared to your market?

Congratulations! As I mentioned earlier, dealerships that are able to have high maintenance effective rates and/or really good MPI process and selling skills can likely have labor gross profit percentages as high as the low 80’s. I would always encourage you to verify that your technicians are fairly compensated and that your maintenance pricing is fair.

A. Verify that your “skill proficiency” is not too low (see 1.C). This could cause your cost-of-sale to be low, but create backlogs of repair work,

imbalance in work distribution (highly skilled techs do all of the difficult work), or quality issues caused by technicians working on repairs that

they are not qualified to perform

B. Is your maintenance retention too low?

- As a rule of thumb, dealerships typically have a maintenance work mix of 50-60%, unless they have either an extremely large fleet repair

operation or you are blessed with a customer base of high mileage (90,000+) vehicles.

- If neither of these apply, and your maintenance % is too low, then one of the two following items are true:

1. Your team is doing oil changes and not selling additional needed maintenance items. Menu presentation is a must!

2. Your customers are not returning for maintenance. This is typically caused by inconvenience or a dislike of the dealership’s service

department. Unfortunately, if they do not visit you for maintenance, they are highly unlikely to visit you for customer pay repairs.

3. Your door rate already higher but you’re not getting this gross percentage – This would generally point me in the direction of pricing policy adherence. Are your advisors playing “let’s make a deal” with their customers? If so, why? Are they not communicating properly, then making a deal to appease the customer?

A. Implement a written Labor Pricing Policy, defining the advisor’s limit on giving discounts. Have each advisor sign the policy. (email me for template)

B. Train advisors in relationship selling. If your team is average, then your service is a commodity…price becomes a big factor.

Summary

While I realize that this exercise may be like taking a drink from a fire hydrant, it is really not that difficult. What I have attempted to do is to expose most of the variables. Remember, what looks good is not always great...and, what looks bad is not always terrible. Progress is possible...it just requires an understanding of your business. Remember Newton's law: "For every action, there is an equal and opposite reaction." The better that you understand these reactions, the more successful you will be in growing your business. Feel free to contact me by phone (904-237-2375), or email me.