Retaining Technicians

This MUST be a key focus! Your opportunity for success is slim if you fail to retain a significant portion of your current technicians. So, how do we do this?

#1 - Culture - Does management "talk the walk" or "walk the talk"? How do we show respect to our technicians? Many managers think of technicians as “cry-babies”, always complaining. Why don’t you organize the communication process and do something about it? This is not about giving your technicians everything. Rather, it's about listening and responding. Here are some techniques:

a) Have a 5-10-minute shop meeting, each morning. Discuss previous day’s production, equipment condition and any other pertinent issues. Keep a running log on issues and address regularly, until resolved.

b) Keep a whiteboard in the shop with unresolved shop issues. This keeps issues on the forefront until they are either resolved or addressed. Sometimes the address is "Welcome to the car business!"

c) If technicians’ express concerns that you cannot change, tell them. Be completely honest. They would rather hear the truth than feel ignored. Once again: "Welcome to the car business!"

#2 – Production – While the majority of technicians don’t really “hate” flat rate, it does cause a couple of disconnects.

a) The mentality that no one cares or that “I just rent an expensive bay from the dealership”.

b) Lack of trust in the manufacturers' labor times.

As we saw in the technician surveys, the #1 cause of technicians leaving was unfair pay, and #2 was unfair work distribution. These issues are almost the same.

We cannot expect technicians to self-regulate their production! We must help them. So how do we do this?

• Set and agree on Production Objectives. Whether technicians are paid hourly, salary, flat-rate or any combination…you MUST have processes in place to manage this. The technicians must be a part of setting production objectives. Don’t expect great results if you “assign” objectives.

• Manage Production – Review flagged hours every day! When a technician misses their objective, understand why. Problem jobs? Lack of training? Jobs not flagged? etc. Show them that you care. Would it be practical to give him/her a “gravy” job to help offset?

Your department sells flat rate hours. If you don’t manage them, how do you know your inventory? By actively, accurately, managing your production, you will accomplish three things:

1. Improved Production – What gets measured, gets done!

2. Improved Morale – Technician feel that they are a part of the company and that dispatch is fair.

3. Improved Forecasting – Flagged hours times Effective Rate equals Labor Sales. This gives you the tools to accurately track and manage your labor sales, rather than just hoping.

#3 – Compensation – In the survey, technicians expressed concerns with warranty labor times and a desire to have an assurance of not starving in slow times. Chances are that if your dealership performs well in #1 (Culture) and #2 (Production), chances are compensation is not as big of an issue as if you don’t.

I think it’s fair to say that the dealerships that do a better job in all three of these areas are going to be the winners. So how do we offer a fairer compensation package, and who will dare to do it?

Option 1– Managed Production – As mentioned above, proper management of production will offset many of the concerns that technicians experience. This requires a sincere focus from management.

• Set and agree on production objective with each technician, individually. The discussion should go like this: “Your average production for the last 10 weeks has been -- hours per day. Does that sound correct?”; “Could you do more than that?”; “If so, what would need to happen?” Listen to his/her concerns and address each. Can you improve each item or is it just the way it is? Once you have agreed on any changes, ask for a number of hours that he/she could perform in a quality manner. Limit each increase to 15% maximum improvement.

• Once Objectives have been set, determine a method of documenting flagged hours before the workday begins. Determine who is going to do morning production meetings (Dispatcher, Shop Foreman, Group Leader, Service Manager, etc.)?

• Each morning, the designated person is to meet with all technicians to discuss their previous day’s and week-to-date performance to discuss any shortcomings and device a plan of improvement. If anyone other than the Service Manager is performing these discussions, it is extremely important that the manager is involved (attending meetings, singling out under-performing technicians, etc.)

Option 2 – Warranty Pay Rates - Most states require the manufacturer to pay the dealer their retail repair rate for warranty repairs. Why not pay the technician on a two-tier pay plan? Here is an example:

• Customer Pay Repair Effective Rate (Door Rate) $120.00 - 50% of CP Work = $60.00

• Customer Pay Maintenance Effective Rate $ 60.00 - 50% of CP Work = $30.00

Overall CP Effective Labor Rate $90.00 ($60.00 + $30.00)

• Desired Labor Gross Profit 75% Average Technician Rate 25% X $90.00 = $22.50

• Warranty Labor Rate (Retail Option) $120.00 Average Technician Rate 25% X $120.00 = $30.00

In this case, each technician would be paid a 33.3% higher rate to perform warranty repairs.

1. Would this make technicians feel that warranty work was fairer?

2. In many cases this might lower warranty gross profit, but what would the offset in hiring and employee retention be?

3. If you choose to implement Option 2, we highly recommend that you also implement Option 1.

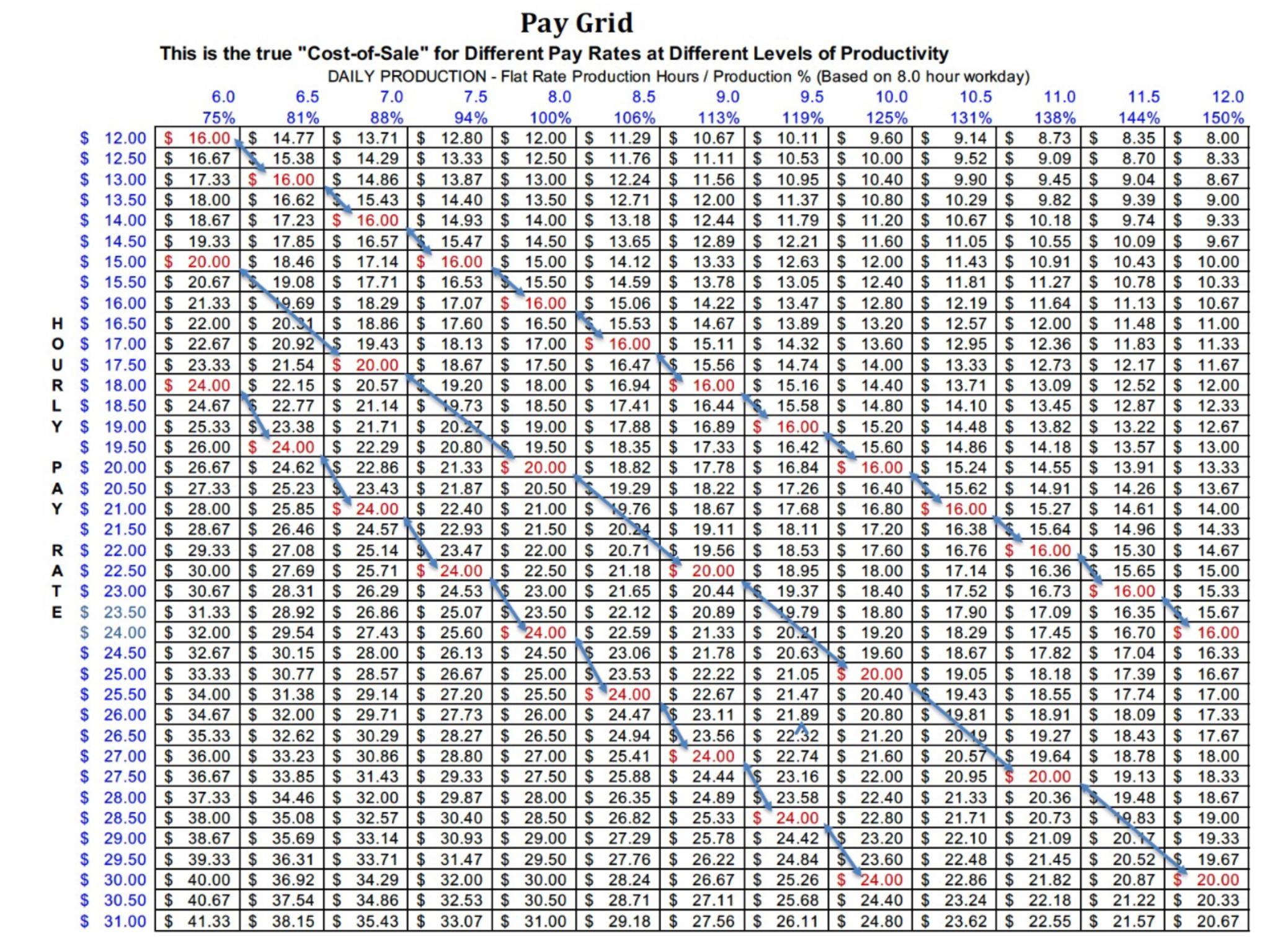

Option 3 - Hourly Pay Plan with Incentive - This pay plan has, traditionally, been referred to as a derivative of a PMI or Per-Man-Hour-Invested. In this design, every month is an "earn-in-period" for the following month. The technician is paid a clock-hour rate, based on their productivity from the previous month. The "cool part" of this pay-plan is that your cost-of-sale can remain constant. This graph will illustrate:

In this grid, let's say that we have three levels of technicians, A,B and C.

An "A" technician who is 75% productive in the earn-in-period, will be paid $18.00 per clock hour the following month. At 81%, they will be paid $19.50 per hour...all the way to $30.00 per hour if they were 125% productive during the earn-in-period. In every case, your cost-of-sale is $24.00 per hour.

Similar situations for "B" and "C" level technicians and you could cap at a rate. Example: A "B" technician might cap at $27.50 at 138% productivity. In this case, your cost-of-sales is $20.00 per hour. If a "C" technician is 100% productive during the earn-in-period, they will be paid $16.00 per clock hour, the next month.

In all of these cases, it is important to calculate earn-in based on productivity percentage, rather than hours flagged. This prevents technicians from "milking-the-clock" for additional hours. Want us to build you a grid? Let me know.